Operations

41

production sites

24

carbon-neutral sites in 2017, including 9 factories

100

quality verifications on average for each product

3 “A”

ratings from CDP x

Highlights

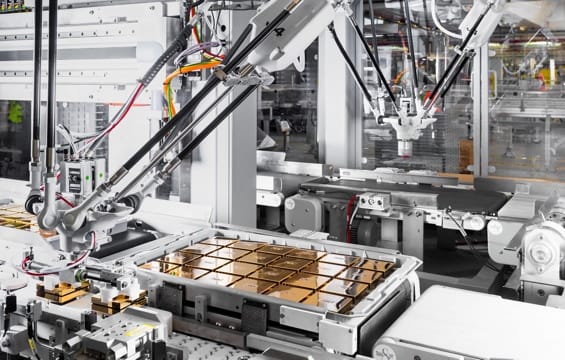

Improving agility, from prototyping to distribution

New technologies are allowing us to improve production processes and enhance our flexibility and efficiency to benefit consumers.

A backstage look at e-commerce: an agile, digital supply chain

With the rise of e-commerce, new delivery methods are being developed, encouraging us to change the way we prepare and send out orders. The entire L’Oréal supply chain is undergoing a transformation to improve agility and keep in step with this revolution.

Read more100% responsible packaging is possible!

As they become increasingly attuned to environmental issues, consumers incorporate this concern into their purchasing behaviours: they want safe, qualitative, innovative products that are also environmentally-friendly. Packaging – the most important marker of brand identity for consumers – plays a crucial role in their purchasing choices.

Read moreOperational excellence and cost management create value

Operational excellence and cost management have steadily optimised the Group’s performance, with a 20% increase in global production since 2008 and a stable industrial footprint (including factories at end 2017). Operational excellence and cost management drive L’Oréal’s competitive edge and contribute to the Group’s growth worldwide.

Read more

Sustainable, solidarity-sourced vanilla in your beauty products

Consumers want more natural cosmetics products and are looking to inform themselves about natural ingredient sourcing. At L’Oréal, Bourbon vanilla is used to create fragrances. Worldwide, 80% of vanilla comes from Madagascar, particularly from the north-eastern part of the country. Production is very fragmented, with thousands of small farms. L’Oréal is taking action on the ground to help organise the sector and make it sustainable.

The goal is to verify the origin and quality of the vanilla, better support farmers as they increase production while taking their expectations into account; and to maintain quality vanilla plants year-round. Yearly audits are conducted to ensure the sector’s sustainability.

Beauty industry leader recognised for environmental initiatives

For the second consecutive year, L’Oréal was recognised for its benchmark environmental commitment by CDP, an independent international organisation that evaluates companies’ environmental performance. The Group is one of just two companies to receive “A” ratings in each of the three categories: climate change action, sustainable water management, and the fight against deforestation.

Read the transcript of this podcast

L’Oréal opens first “dry” factory

In 2017, the Burgos factory in Spain become L’Oréal’s first “dry” factory: the site only withdraws water for use in product formulas and for on-site human consumption. The water used for industrial processes is purified and recycled in a closed loop. The factory has its own wastewater treatment facility. Once treated, the high-quality water is reused to cover the factory’s needs (cooling, washing equipment, etc.).

Logistics committed to protecting the planet

Sustainable development is at the heart of the supply chain strategy. To reduce the environmental footprint of transport activities, L’Oréal has launched a new global initiative to foster cooperation with transport companies and co-create custom environmental solutions suited to each geographical Zone. The idea is to bring together local and international transport companies in each geographical Zone to launch cooperative programmes in line with L’Oréal’s vision and commitments as outlined by the “Sharing Beauty With All” corporate social responsibility programme.